900 319 0030

enquiry@shankarias.in

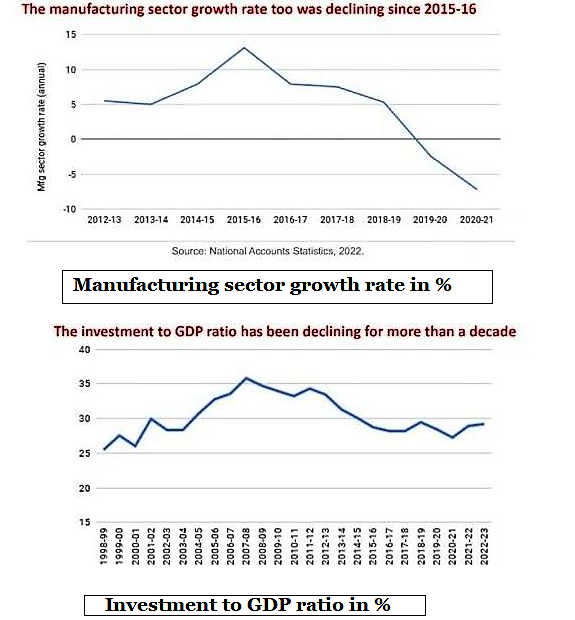

The growth rate of manufacturing productivity in India is in negative trend which got accelerated during COVID-19.

India is the 3rd most sought-after manufacturing destination in the world and has the potential to export goods worth US$ 1 trillion by 2030.

|

Steps Taken to Promote the Manufacturing Sector |

|

References